- Home

- Glossary Term

- Sales and Operations Planning

Introduction

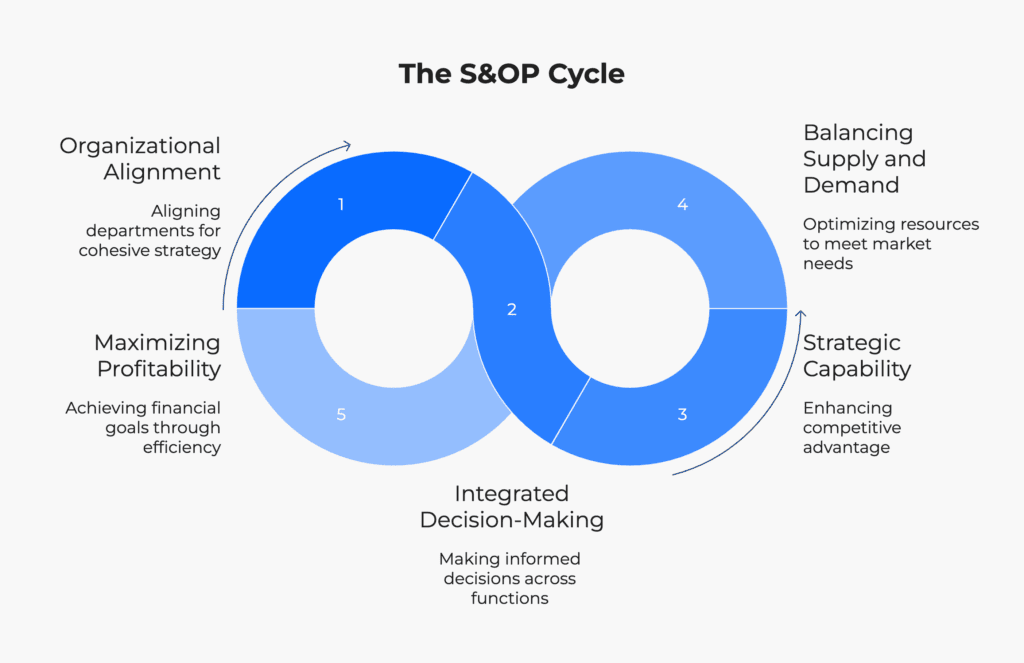

Sales and Operations Planning (S&OP) represents a fundamental business management process that creates organizational alignment and drives competitive advantage through integrated decision-making. As market volatility increases and supply chains become more complex, S&OP has evolved from a traditional planning exercise into a critical strategic capability that enables companies to balance supply and demand while maximizing profitability.

What is Sales and Operations Planning?

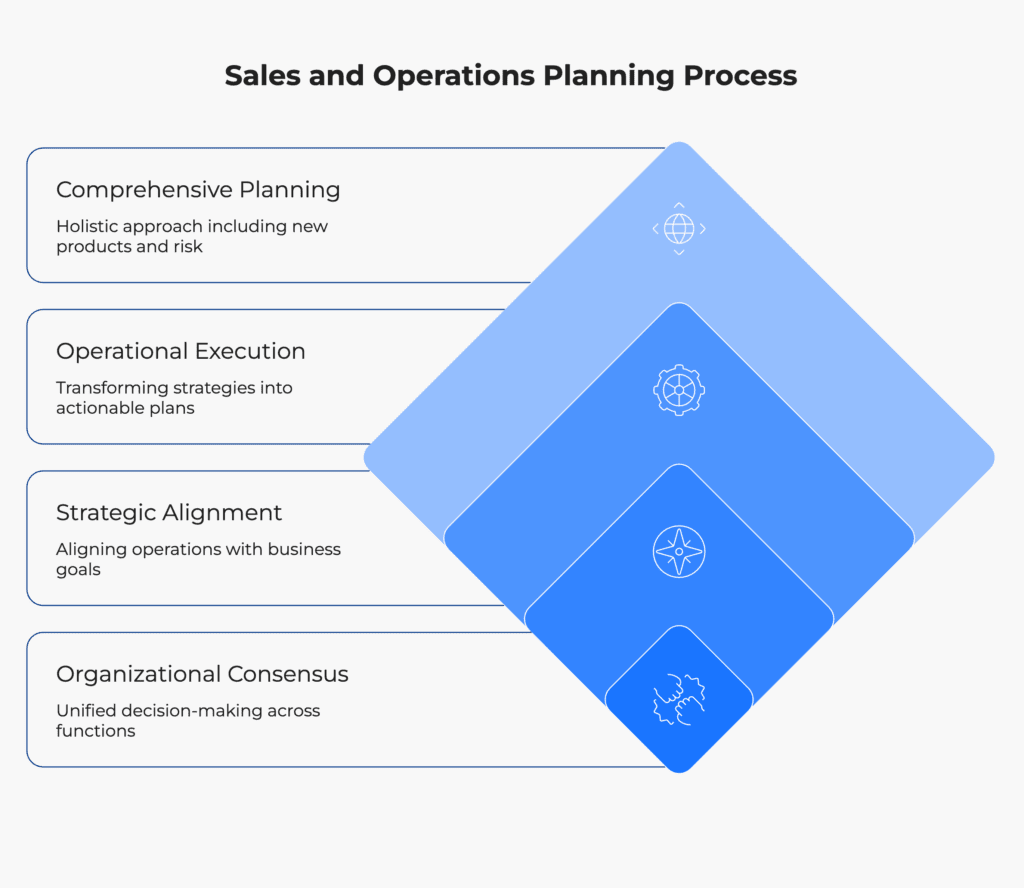

Sales and Operations Planning is an integrated business management process that drives organizational consensus to balance supply and demand while aligning operational areas with strategic business goals. The process brings together stakeholders from sales, marketing, product development, manufacturing, procurement, finance, and other functions to create unified operational plans that extend 18 to 36 months into the future.

At its core, S&OP serves as the bridge between strategic planning and operational execution, transforming high-level business strategies into actionable plans while providing feedback on performance and market dynamics. The process establishes clear accountability for plans, creates transparency across functional areas, and enables agile responses to changing market conditions.

Modern S&OP extends beyond traditional supply chain planning to encompass comprehensive business planning that includes new product introductions, market expansion strategies, financial planning, and risk management. This holistic approach ensures that all organizational functions work toward common objectives while maintaining operational efficiency and customer satisfaction.

Core Components and Process Framework

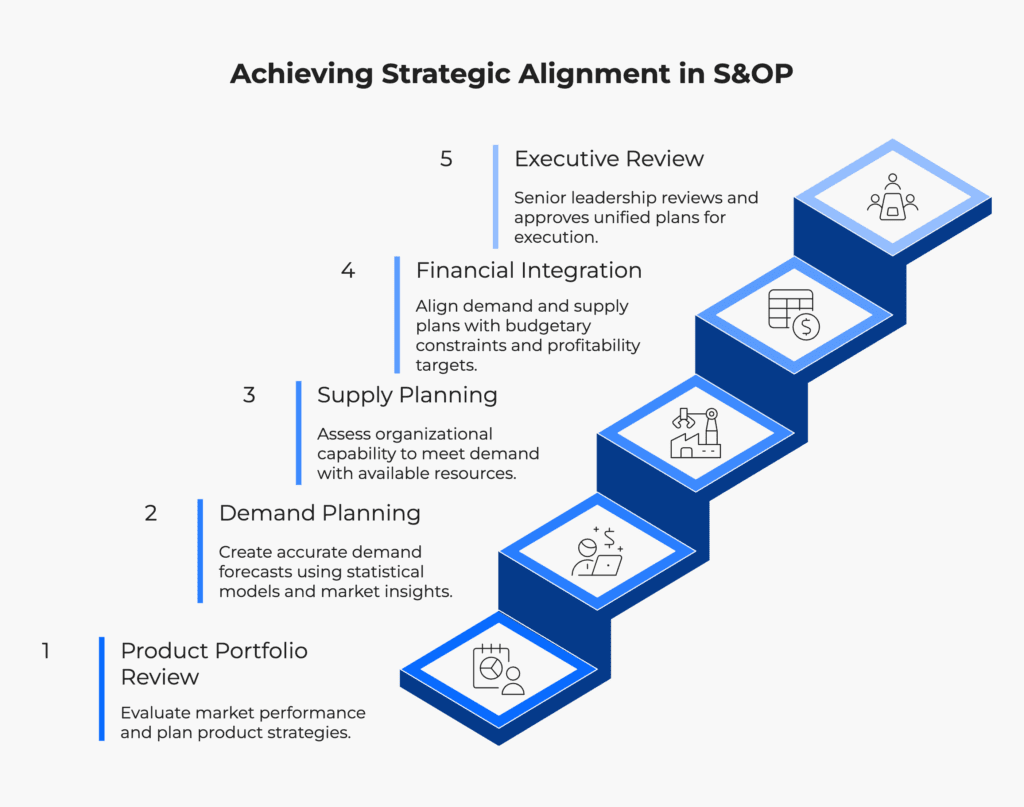

Product Portfolio Review

The S&OP process begins with comprehensive product portfolio analysis, where planners evaluate market performance, examine product pipelines, and make strategic decisions about product planning. This phase involves analyzing product life cycle stages, assessing new product launches, and identifying obsolete items requiring phase-out strategies.

Product review activities include market performance evaluation, competitive analysis, and resource allocation decisions that determine project prioritization and development timelines. The process considers cannibalization effects of new products on existing offerings while establishing launch dates and sunset schedules that optimize overall portfolio performance.

Demand Planning and Forecasting

Demand planning creates comprehensive demand forecasts by integrating statistical models with market intelligence, sales insights, and marketing plans. The process incorporates both independent demand from customers and dependent demand from internal operations, creating consensus forecasts that reflect realistic market expectations.

Advanced demand planning leverages artificial intelligence and machine learning to analyze historical patterns, seasonal trends, and market dynamics while incorporating customer feedback and competitive intelligence. The goal is creating unconstrained demand plans that provide accurate input for supply planning and resource allocation decisions.

Supply and Production Planning

Supply planning evaluates organizational capability to meet forecasted demand through available resources, including manufacturing capacity, raw materials, and workforce availability. The process creates production plans that balance customer service requirements with inventory optimization and operational cost control.

Supply planning activities include capacity analysis, rough-cut capacity planning, and alternative supply scenario evaluation using real-time data and what-if modeling capabilities. The process identifies constraints, bottlenecks, and resource gaps while developing contingency plans that address potential disruptions and demand variations.

Financial Integration and Reconciliation

Financial reconciliation ensures that demand and supply plans align with budgetary constraints and profitability targets. This phase evaluates the financial viability of proposed plans, identifying revenue gaps and cost implications while ensuring alignment with overall business objectives.

The financial review process reconciles demand, supply, and financial plans to create balanced operational blueprints that meet customer requirements while maintaining profitability. This integration enables informed decision-making that considers both operational feasibility and financial impact.

Executive Review and Decision Making

The executive S&OP meeting represents the culmination of the planning process, where senior leadership reviews consolidated plans and makes strategic decisions. This phase brings together cross-functional leaders to approve unified plans that serve as operational blueprints for the organization.

Executive meetings focus on significant gaps, strategic decisions, and resource allocation choices that require leadership approval. The process establishes clear accountability for plan execution while providing visibility into performance metrics and market dynamics that inform strategic adjustments.

Key Benefits and Business Impact

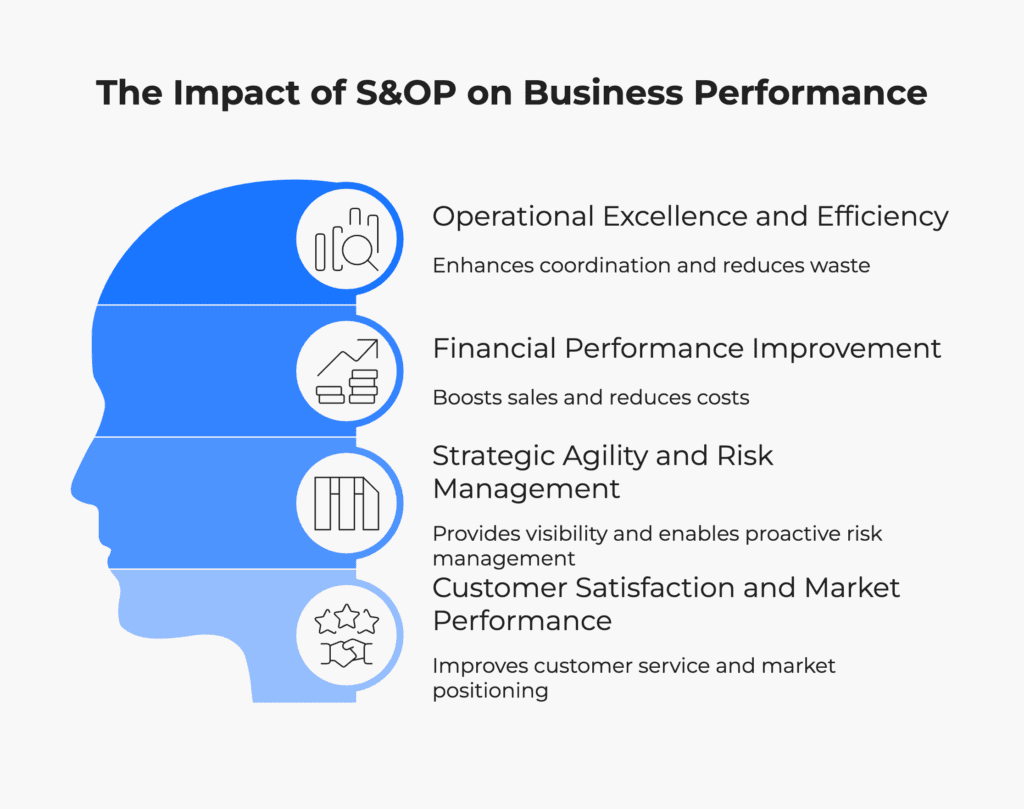

Operational Excellence and Efficiency

S&OP implementation drives significant operational improvements through enhanced coordination, reduced waste, and optimized resource utilization. Organizations implementing mature S&OP processes experience 50-80% lower inventory levels while achieving 15% higher on-time delivery performance and 40-64% shorter cash-to-cash cycle times.

The process eliminates departmental silos, improves cross-functional collaboration, and creates unified data environments that support informed decision-making. Advanced S&OP implementations leverage artificial intelligence and machine learning to enhance forecast accuracy and optimize resource allocation automatically.

Financial Performance Improvement

Research indicates that organizations implementing comprehensive S&OP processes achieve 2-4% sales growth through improved service levels, new product launches, and promotion effectiveness. Cost reductions of 5-10% result from fixed cost optimization, improved capacity utilization, and reduced expedite costs.

Working capital improvements of 20-30% provide significant cash flow benefits through optimized inventory levels and improved supply chain efficiency. A typical $500 million revenue business can gain approximately $25 million annually in gross margin improvements through effective S&OP implementation.

Strategic Agility and Risk Management

S&OP enhances organizational agility by providing comprehensive visibility into market dynamics, operational constraints, and financial implications of strategic decisions. The process enables proactive risk management through scenario planning, contingency development, and early identification of potential disruptions.

Organizations with mature S&OP processes demonstrate superior responsiveness to market changes, competitive threats, and supply chain disruptions. The integrated planning approach enables rapid strategy adjustments while maintaining operational stability and customer service levels.

Customer Satisfaction and Market Performance

Improved demand forecasting and supply planning capabilities enable organizations to meet customer requirements more consistently while reducing stockouts and delivery delays. Enhanced coordination between sales and operations teams improves communication with customers and enables more accurate delivery commitments.

The process facilitates better customer service through improved inventory management, reduced lead times, and enhanced ability to respond to changing customer requirements. Organizations report improved customer satisfaction scores and stronger competitive positioning as direct results of S&OP implementation.

Implementation Framework and Best Practices

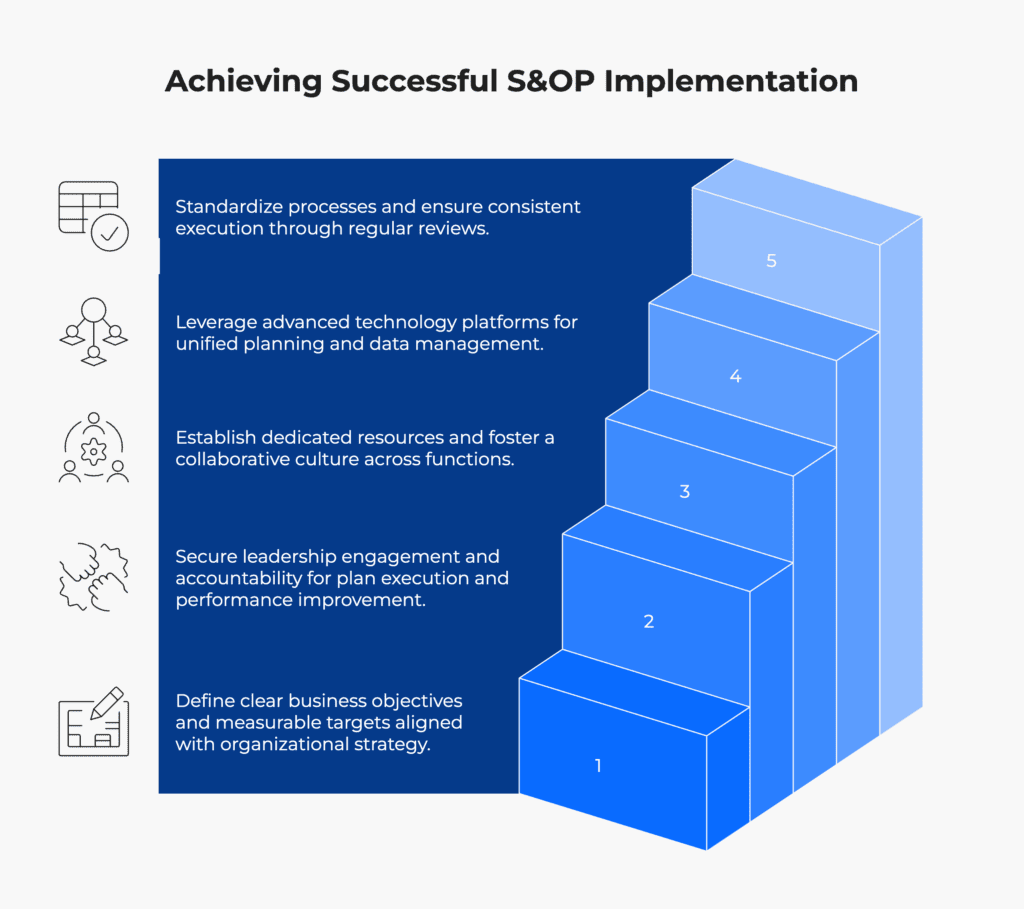

Strategic Foundation and Goal Setting

Successful S&OP implementation begins with clear definition of business objectives, measurable targets, and specific outcomes that align with organizational strategy. Companies must establish baseline metrics for forecast accuracy, inventory turns, customer service levels, and financial performance to measure implementation success.

The process requires executive commitment and cross-functional leadership engagement to ensure that S&OP serves as a management decision-making tool rather than an operational planning exercise. Leadership must actively participate in the process and hold organizations accountable for plan execution and performance improvement.

Organizational Design and Change Management

Effective S&OP implementation requires dedicated organizational resources including S&OP managers, demand planners, supply planners, and financial analysts who coordinate cross-functional activities. The process demands cultural change that emphasizes collaboration, transparency, and shared accountability for business results.

Change management strategies must address resistance to new processes, provide comprehensive training for all participants, and establish clear roles and responsibilities throughout the organization. Success requires breaking down functional silos and creating collaborative environments that support integrated decision-making.

Technology Integration and Data Management

Modern S&OP implementations leverage advanced technology platforms that integrate data from ERP, CRM, and other business systems to create unified planning environments. Cloud-based solutions provide scalability, accessibility, and real-time collaboration capabilities that support global operations.

Technology selection should prioritize platforms that support scenario modeling, what-if analysis, and collaborative planning while providing integration capabilities with existing business systems. Data quality and governance become critical success factors that require ongoing attention and improvement.

Process Standardization and Continuous Improvement

S&OP processes must be standardized, documented, and embedded in organizational routines to ensure consistent execution and measurable results. Monthly planning cycles with defined deliverables, meeting schedules, and approval processes create accountability and momentum for continuous improvement.

Regular process reviews and performance assessments identify optimization opportunities and ensure that S&OP continues to deliver business value as organizational needs evolve. Best-in-class organizations treat S&OP as a continuous improvement journey rather than a one-time implementation project.

Technology Solutions and Digital Transformation

Artificial Intelligence and Machine Learning

Advanced S&OP platforms increasingly incorporate AI and machine learning capabilities to enhance forecast accuracy, automate routine planning tasks, and provide predictive insights that inform strategic decisions. These technologies analyze vast amounts of data to identify patterns, trends, and optimization opportunities that human planners might miss.

AI-powered solutions provide automated exception management, intelligent alerts, and recommendation engines that help planners focus on high-value activities while ensuring that routine tasks are handled efficiently and accurately.

Cloud-Based Collaboration Platforms

Modern S&OP solutions leverage cloud technologies to provide anywhere, anytime access to planning tools and data while supporting real-time collaboration among geographically distributed teams. Cloud platforms offer scalability, automatic updates, and integration capabilities that reduce IT overhead while enhancing functionality.

These platforms enable advanced analytics, scenario modeling, and visualization capabilities that improve decision-making quality while reducing the time required to develop and evaluate alternative plans.

Integrated Business Planning Evolution

S&OP continues evolving toward Integrated Business Planning (IBP) that encompasses broader business functions including product development, capital planning, and strategic initiatives. This evolution reflects growing recognition that planning processes must address entire business ecosystems rather than focusing solely on supply chain operations.

IBP platforms provide comprehensive business modeling capabilities that support strategic planning, operational planning, and performance management within unified environments that eliminate functional silos and improve organizational alignment.

Conclusion

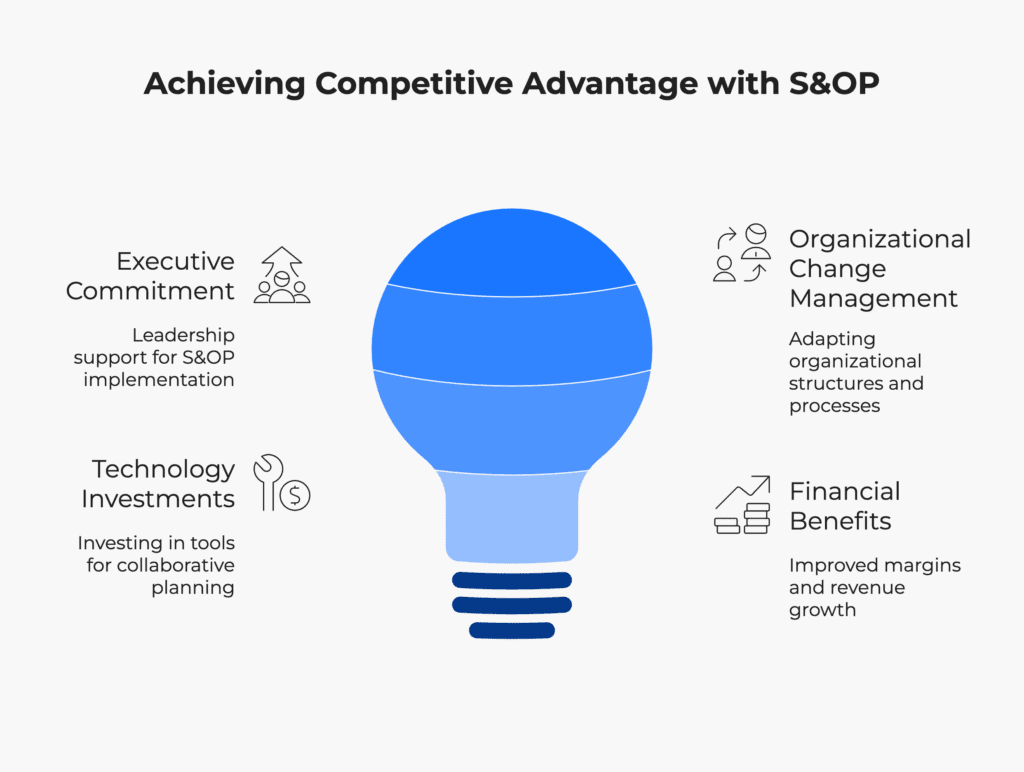

Sales and Operations Planning represents a critical capability for organizations seeking to achieve sustainable competitive advantage through operational excellence and strategic agility. Successful S&OP implementation requires executive commitment, organizational change management, and technology investments that support collaborative planning and decision-making. Organizations that embrace S&OP as a core business process rather than a periodic planning exercise realize significant financial benefits including improved margins, reduced working capital requirements, and accelerated revenue growth.