- Home

- Glossary Term

- Bill of Materials (BOM)

What is a Bill of Materials?

A Bill of Materials (BOM) is a comprehensive, structured list that defines all components, assemblies, raw materials, parts, and quantities required to manufacture a finished product. Think of it as the master recipe for production—providing detailed specifications, part numbers, descriptions, and hierarchical relationships that guide manufacturing processes, procurement activities, and cost calculations throughout the product lifecycle.

The power of modern BOMs lies in their integration capabilities. They connect seamlessly with Enterprise Resource Planning (ERP) systems, Product Lifecycle Management (PLM) platforms, and Manufacturing Execution Systems (MES) to create unified product definition frameworks. Digital BOM management leverages real-time data synchronization and automated change control to ensure accuracy while supporting complex product configurations and global manufacturing operations.

Core Components of Bill of Materials

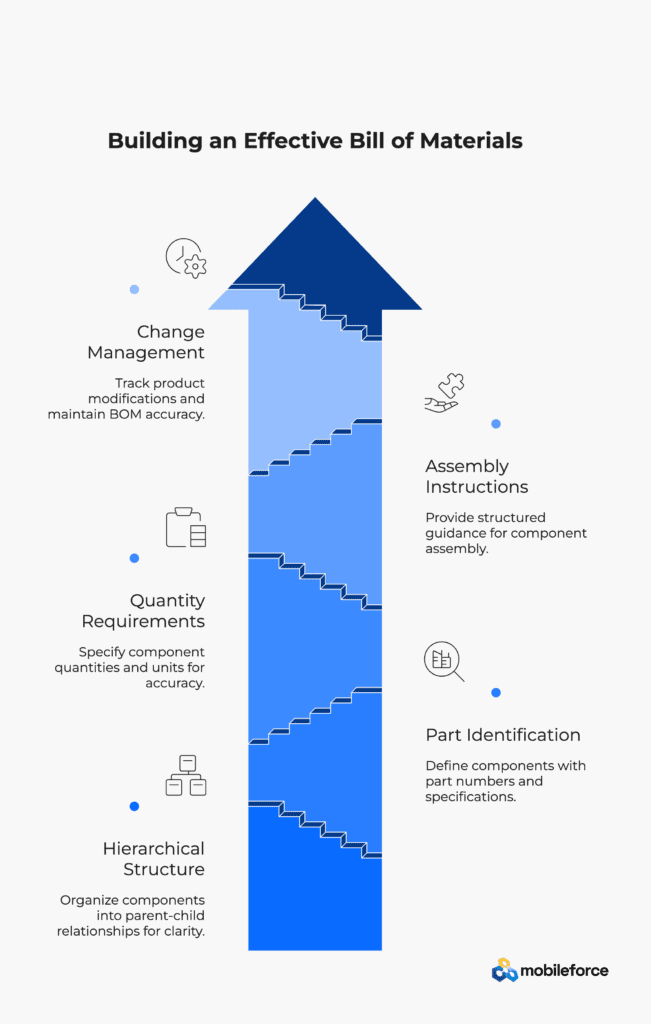

Hierarchical Product Structure

At its foundation, every effective BOM uses systematic organization of product components into parent-child relationships that reflect assembly sequences and manufacturing stages. Hierarchical structures enable clear understanding of product complexity while supporting modular design approaches and standardized manufacturing processes across product families.

Part Identification and Specifications

Beyond structure, BOMs require detailed component definitions including part numbers, descriptions, specifications, and supplier information that ensure precise procurement and manufacturing execution. Part identification provides unambiguous component references while maintaining consistency across engineering, procurement, and manufacturing functions.

Quantity Requirements and Units

Equally critical are precise specifications of component quantities needed per finished product unit, including measurement units and waste factors. Quantity definitions enable accurate material planning while supporting cost calculations and inventory management based on production volume requirements.

Assembly Instructions and Sequences

To ensure consistent execution, BOMs include structured guidance for component assembly including order of operations, assembly methods, and quality checkpoints. Assembly instructions ensure consistent manufacturing execution while supporting workforce training and automated production system programming.

Engineering Change Management

Finally, BOMs incorporate systematic tracking of product modifications, revision histories, and approval workflows that maintain BOM accuracy throughout product lifecycles. Change management ensures all stakeholders work with current product definitions while maintaining audit trails for compliance and quality control.

Types of Bill of Materials

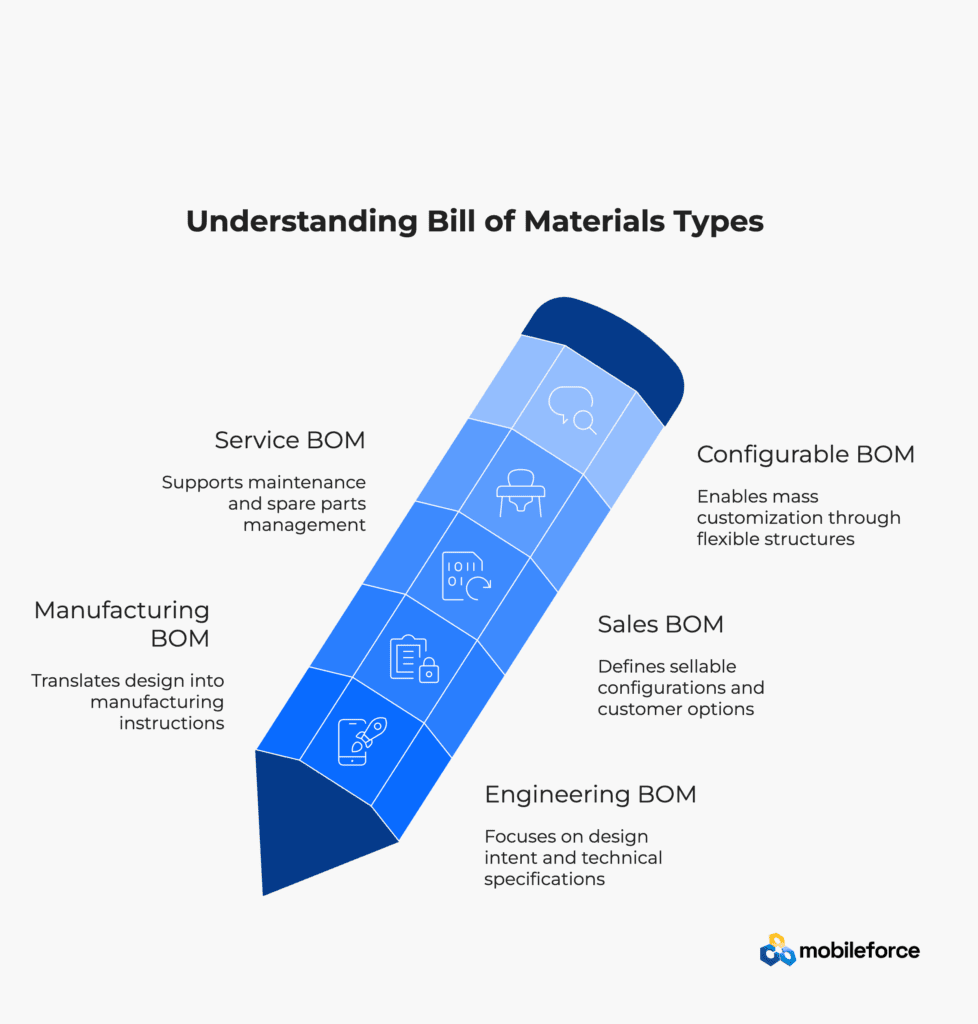

Different organizational needs require specialized BOM types, each serving distinct purposes within the product lifecycle.

Engineering BOM (EBOM)

Engineering teams create product structures that define design intent, component relationships, and technical specifications. EBOMs focus on functionality and design requirements while serving as foundation for manufacturing and procurement planning activities.

Manufacturing BOM (MBOM)

Production teams work with structures that define how products are actually built, including assembly sequences, work centers, and manufacturing processes. MBOMs translate design intent into executable manufacturing instructions while optimizing production efficiency and resource utilization.

Sales BOM (SBOM)

Meanwhile, customer-facing product structures define sellable configurations, options, and features available for customer selection. SBOMs enable Configure Price Quote (CPQ) systems while supporting sales processes and customer communication about product capabilities and customization options.

Service BOM (SrBOM)

Service organizations require maintenance-focused structures that define spare parts, service procedures, and replacement components required for product support throughout operational lifecycles. Service BOMs enable field service management while supporting aftermarket revenue streams and customer satisfaction initiatives.

Configurable BOM (CBOM)

For mass customization needs, flexible product structures accommodate multiple product variants and customer-specific configurations through rules-based component selection. Configurable BOMs enable mass customization while maintaining manufacturing efficiency through standardized base platforms and optional components.

Key Benefits of BOM Management

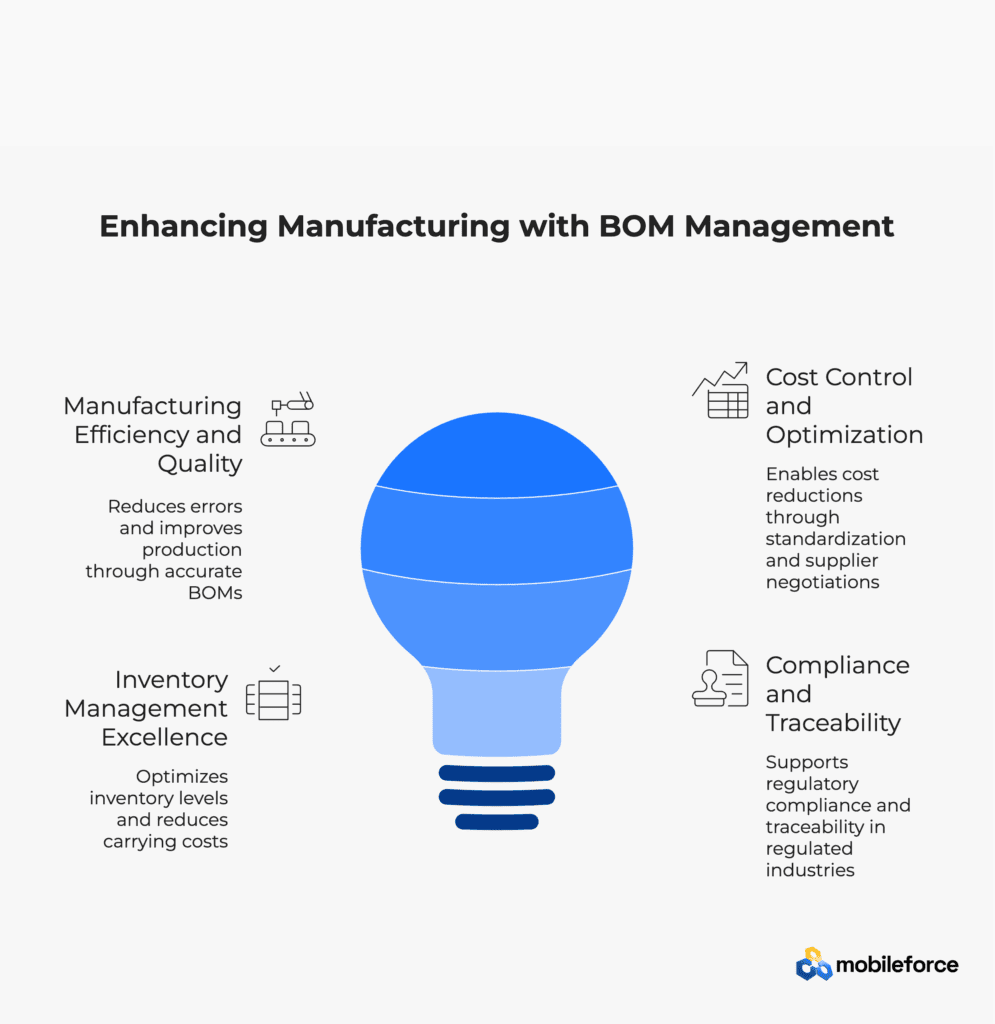

The systematic approach to BOM management delivers measurable improvements across multiple aspects of manufacturing operations.

Manufacturing Efficiency and Quality

Organizations implementing comprehensive BOM management achieve 20-35% reductions in manufacturing errors and 15-25% improvements in production efficiency. The mechanism behind these gains involves accurate BOMs that eliminate assembly confusion while ensuring consistent product quality through standardized specifications and clear assembly instructions.

Cost Control and Optimization

From a financial perspective, detailed BOM analysis enables precise cost calculations and identifies optimization opportunities through component standardization and supplier consolidation. Companies report 10-20% cost reductions through systematic BOM analysis that eliminates redundant parts while negotiating volume discounts with strategic suppliers.

Inventory Management Excellence

Operational benefits extend to inventory optimization, where accurate BOMs support precise material requirements planning that reduces inventory carrying costs while preventing stockouts. Organizations achieve 25-40% inventory optimization through disciplined BOM management that balances material availability with working capital efficiency.

Compliance and Traceability

In regulated industries, comprehensive BOM documentation supports regulatory compliance and quality traceability requirements across sectors including automotive, aerospace, and medical devices. Traceability capabilities enable rapid response to quality issues while maintaining audit trails for regulatory approval and certification processes.

Supply Chain Integration Benefits

BOMs serve as the foundation for sophisticated supply chain management capabilities that extend far beyond basic component lists.

Supplier Collaboration and Management

Through standardized communication tools, BOMs enable effective supplier relationships and vendor-managed inventory programs. Supplier integration improves through shared BOM visibility while reducing procurement overhead through automated ordering and delivery coordination based on production schedules.

Global Manufacturing Coordination

For multinational operations, standardized BOMs enable consistent production across multiple manufacturing locations while supporting global supply chain optimization. Multi-site coordination improves through unified product definitions while maintaining quality consistency regardless of production location or supplier network configuration.

Risk Mitigation and Continuity

Strategically, BOM analysis identifies single-source components and supply chain vulnerabilities that require risk mitigation strategies. Proactive risk management through BOM intelligence prevents production disruptions while enabling rapid supplier substitution and alternative sourcing when supply challenges arise.

Product Development and Innovation

BOMs play an increasingly important role in driving product development efficiency and innovation capabilities.

Design for Manufacturability

Integration with engineering processes ensures new products consider manufacturing constraints and cost implications during design phases. Early manufacturing input reduces development cycles while optimizing product designs for efficient production and competitive cost structures.

Modular Design and Standardization

Furthermore, BOM analysis reveals component commonality opportunities that enable platform-based product development and reduced complexity. Standardization strategies improve through systematic BOM optimization while maintaining product differentiation through strategic component variation and customer-specific configurations.

Product Lifecycle Optimization

Over time, historical BOM data provides insights into component performance, supplier reliability, and cost trends that inform future product development decisions. Lifecycle optimization benefits from BOM intelligence while supporting sustainable design practices and end-of-life planning through material recovery and recycling programs.

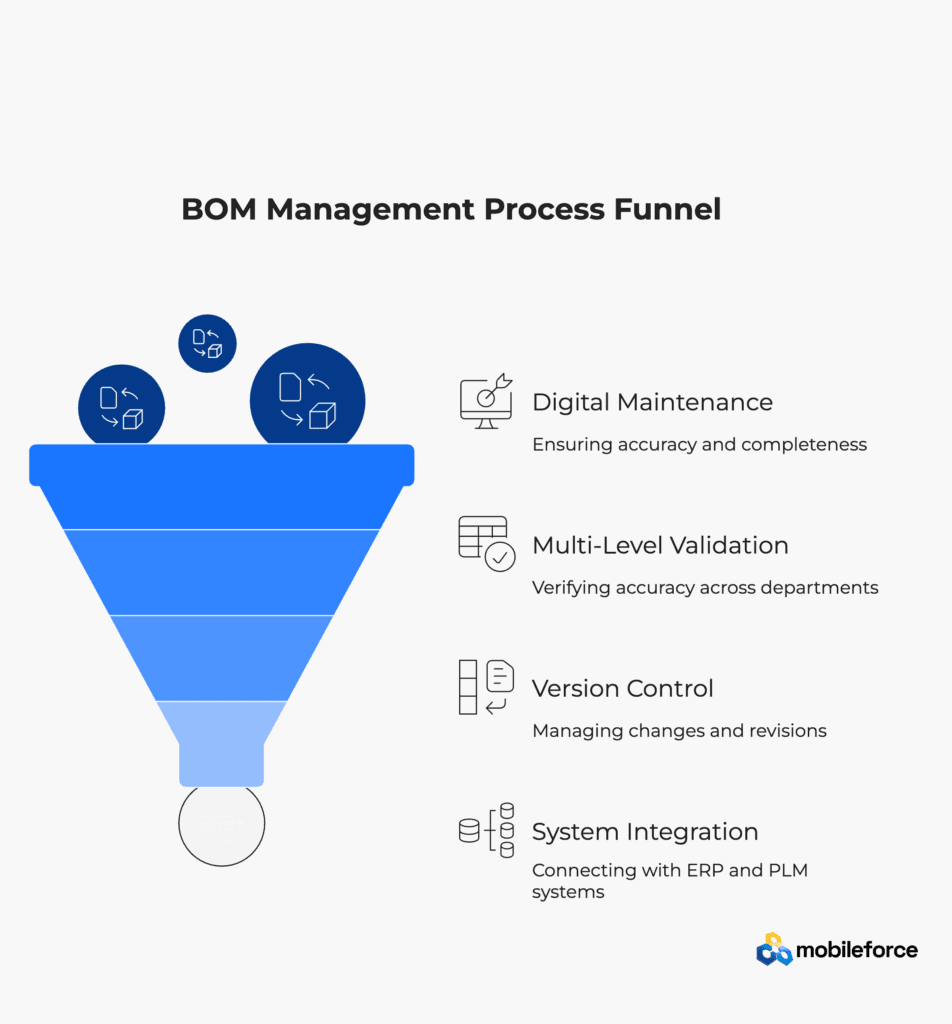

BOM Implementation and Management

Achieving BOM excellence requires more than understanding its components and benefits—organizations must develop systematic approaches to creation, maintenance, and governance that ensure long-term accuracy and utility.

Digital BOM Creation and Maintenance

Starting with the fundamentals, successful implementation demands systematic processes for BOM development, validation, and ongoing maintenance that ensure accuracy and completeness throughout product lifecycles. Digital management eliminates paper-based inconsistencies while enabling real-time collaboration between engineering, manufacturing, and procurement teams.

Multi-Level Validation and Approval

Quality assurance, however, goes beyond initial creation. Comprehensive review processes must verify BOM accuracy across engineering, manufacturing, quality, and procurement perspectives before production release. These validation workflows prevent costly errors while ensuring all stakeholders contribute their specialized expertise to BOM development and optimization decisions.

Version Control and Change Management

Once established, operational integrity hinges on disciplined approaches to BOM modifications that maintain revision histories while coordinating changes across all affected business functions. Change management prevents unauthorized modifications while ensuring production continuity through controlled implementation of necessary product updates and improvements.

Integration with Business Systems

The technical backbone supporting all these processes involves seamless connectivity between BOM management and ERP, PLM, and MES systems that eliminates data duplication while maintaining consistency across business processes. System integration enables automated workflows while providing real-time visibility into BOM status and change impacts.

Technology Infrastructure for BOM Management

With implementation frameworks established, attention turns to the sophisticated technology platforms that enable integration, automation, and real-time collaboration across business functions.

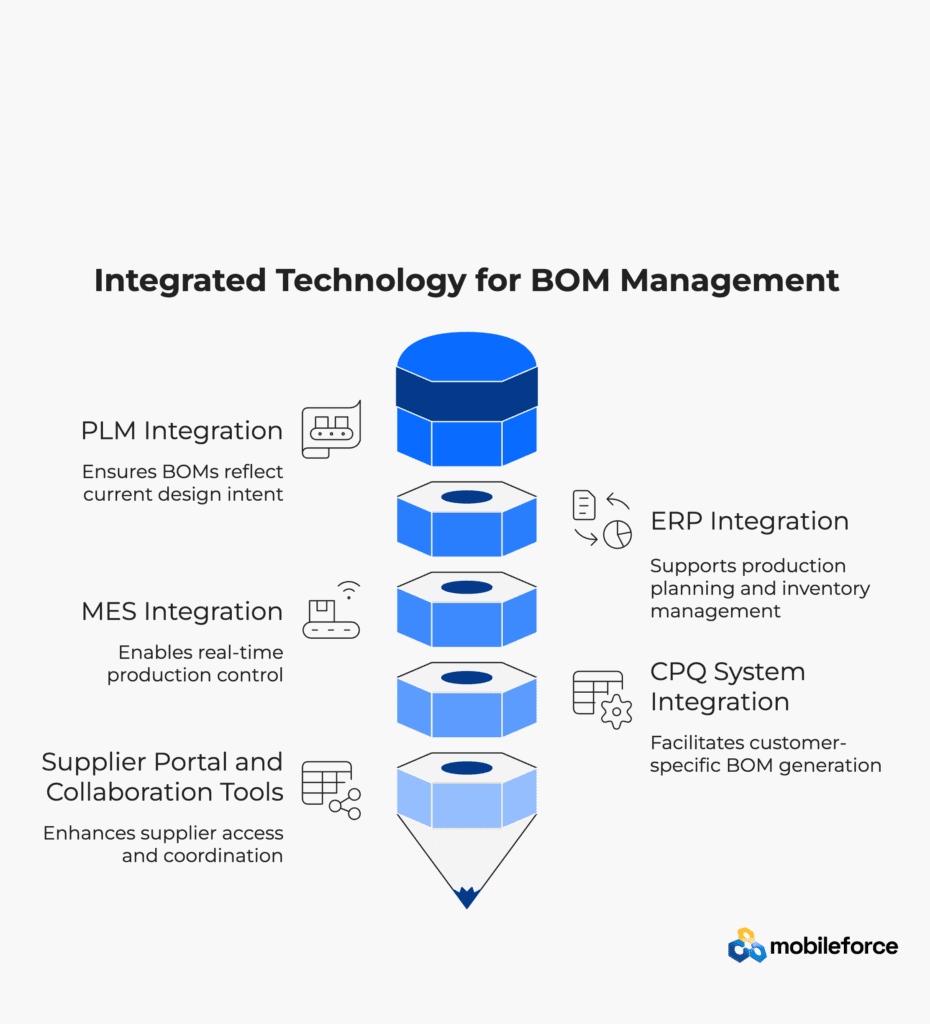

Product Lifecycle Management (PLM) Integration

Beginning with the engineering foundation, organizations need comprehensive connectivity with design systems that maintains BOM synchronization with product development activities. PLM integration ensures BOMs reflect current design intent while supporting collaborative development processes and design change management workflows.

Enterprise Resource Planning (ERP) Integration

Simultaneously, business operations depend on real-time connection with financial and operational systems that enables material requirements planning, cost calculations, and procurement coordination. ERP integration provides comprehensive business context while supporting production planning and inventory management based on accurate BOM data.

Manufacturing Execution System (MES) Integration

On the production side, direct connectivity with shop floor systems translates BOMs into executable work instructions and production schedules. MES integration enables real-time production control while maintaining quality traceability and performance monitoring throughout manufacturing operations.

Configure Price Quote (CPQ) System Integration

From a sales perspective, seamless connection with configuration tools enables customer-specific BOM generation and accurate pricing calculations. CPQ integration supports mass customization while maintaining manufacturing feasibility through rules-based component selection and configuration validation.

Supplier Portal and Collaboration Tools

Extending beyond internal systems, external partnerships require digital platforms that enable supplier access to relevant BOM information for planning, quoting, and delivery coordination. Supplier collaboration improves through shared visibility while reducing communication overhead and improving supply chain responsiveness to production requirements.

BOM Performance Metrics and Analytics

Having established the technological foundation, organizations must implement systematic measurement and analysis capabilities to drive continuous improvement and optimization.

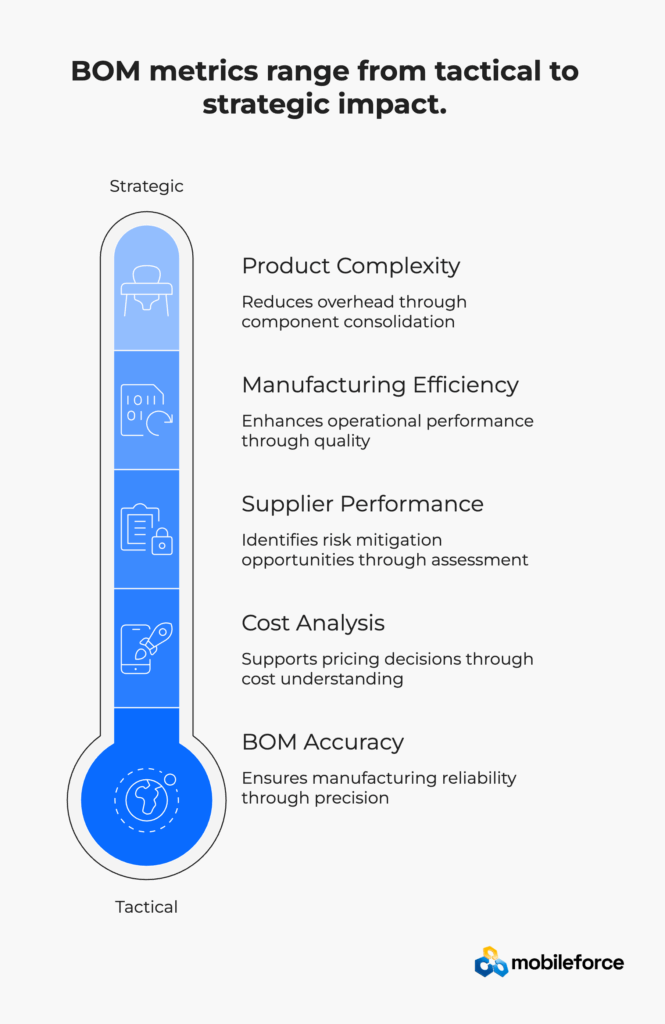

BOM Accuracy and Completeness

Quality metrics serve as the cornerstone, focusing on BOM precision including component specification accuracy, quantity correctness, and structural completeness. Accuracy metrics identify improvement opportunities while ensuring manufacturing reliability through disciplined BOM quality management and validation processes.

Cost Analysis and Optimization

Financial analysis provides another critical dimension through comprehensive evaluation of product costs based on BOM components including material costs, labor requirements, and overhead allocation. Cost analysis reveals optimization opportunities while supporting pricing decisions and profitability management through detailed product cost understanding.

Supplier Performance and Risk Assessment

Supply chain metrics add strategic value through analysis of supplier reliability, quality performance, and delivery consistency based on BOM component requirements. Supplier assessment supports strategic sourcing decisions while identifying risk mitigation opportunities through diversification and alternative supplier development.

Manufacturing Efficiency Impact

Operational metrics complete the picture by examining correlation between BOM quality and manufacturing performance including error rates, rework frequency, and production cycle times. Efficiency analysis validates BOM management investment while identifying specific improvement opportunities that enhance operational performance.

Product Complexity and Standardization

Strategic metrics provide the highest-level perspective through evaluation of product design complexity and component commonality across product portfolios that reveals standardization opportunities. Complexity analysis supports design optimization while reducing manufacturing overhead through strategic component consolidation and platform development.

Advanced BOM Capabilities

As organizations mature their BOM management practices, emerging technologies are transforming capabilities and enabling new levels of optimization and intelligence.

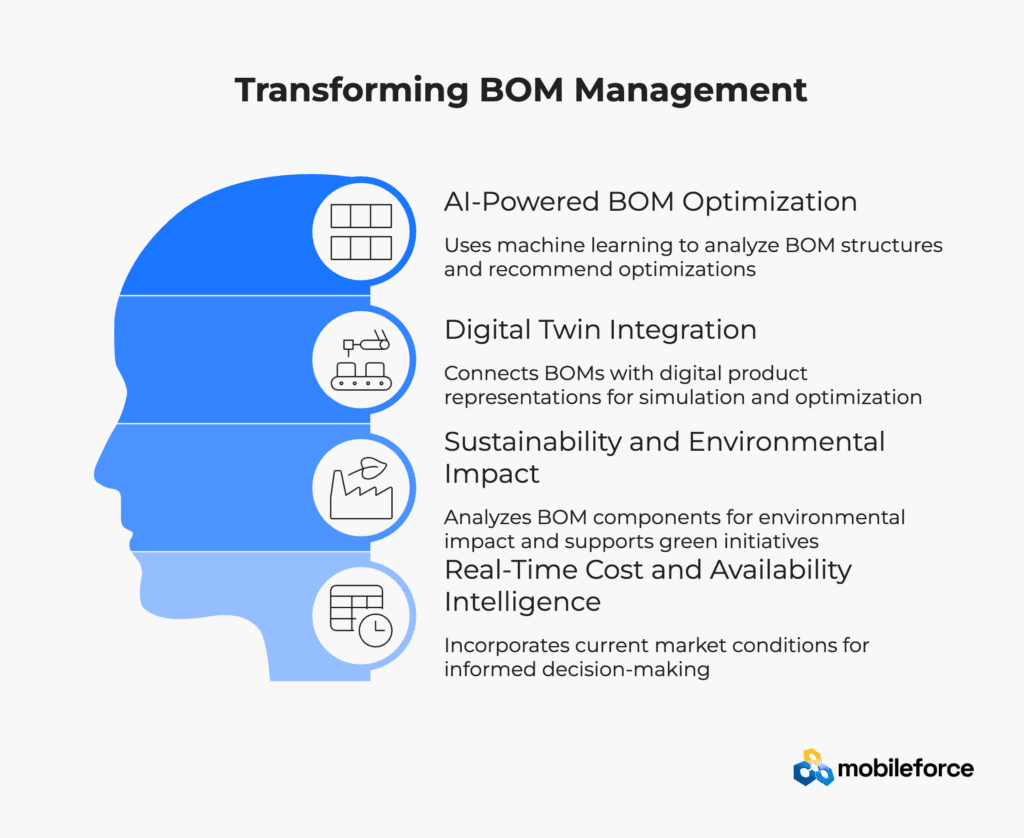

AI-Powered BOM Optimization

Leading the technological evolution, machine learning algorithms analyze BOM structures, cost patterns, and supplier performance to recommend optimization opportunities. AI capabilities enable predictive analysis while identifying component substitution and standardization opportunities that improve cost and efficiency performance.

Digital Twin Integration

Pushing boundaries further, advanced implementations connect BOMs with digital product representations that enable virtual manufacturing simulation and optimization. Digital twin capabilities support design validation while enabling predictive maintenance and performance optimization through integrated product and process modeling.

Sustainability and Environmental Impact

Addressing contemporary concerns, environmental considerations now include analysis of BOM components for environmental impact, recyclability, and sustainability metrics that support green manufacturing initiatives. Sustainability integration enables responsible product development while meeting regulatory requirements and customer expectations for environmental stewardship.

Real-Time Cost and Availability Intelligence

At the cutting edge, dynamic capabilities incorporate current material costs, supplier availability, and market conditions into BOM analysis for informed decision-making. Real-time intelligence enables responsive procurement while supporting flexible manufacturing strategies that adapt to supply chain variations and market opportunities.

Conclusion

Understanding Bill of Materials principles and management strategies is essential for organizations seeking to optimize their manufacturing operations, supply chain performance, and product development effectiveness. Modern BOM management integrates seamlessly with PLM, ERP, and MES systems to provide comprehensive product definition frameworks that support informed decision-making across engineering, manufacturing, and business functions.

For organizations evaluating BOM management solutions, these principles provide the foundation for creating systematic approaches to product definition and manufacturing excellence. The right BOM framework combines sophisticated analytics with proven manufacturing methodologies, positioning organizations to achieve superior operational efficiency, enhanced product quality, and sustainable competitive advantages through disciplined product structure management and optimization.